Description

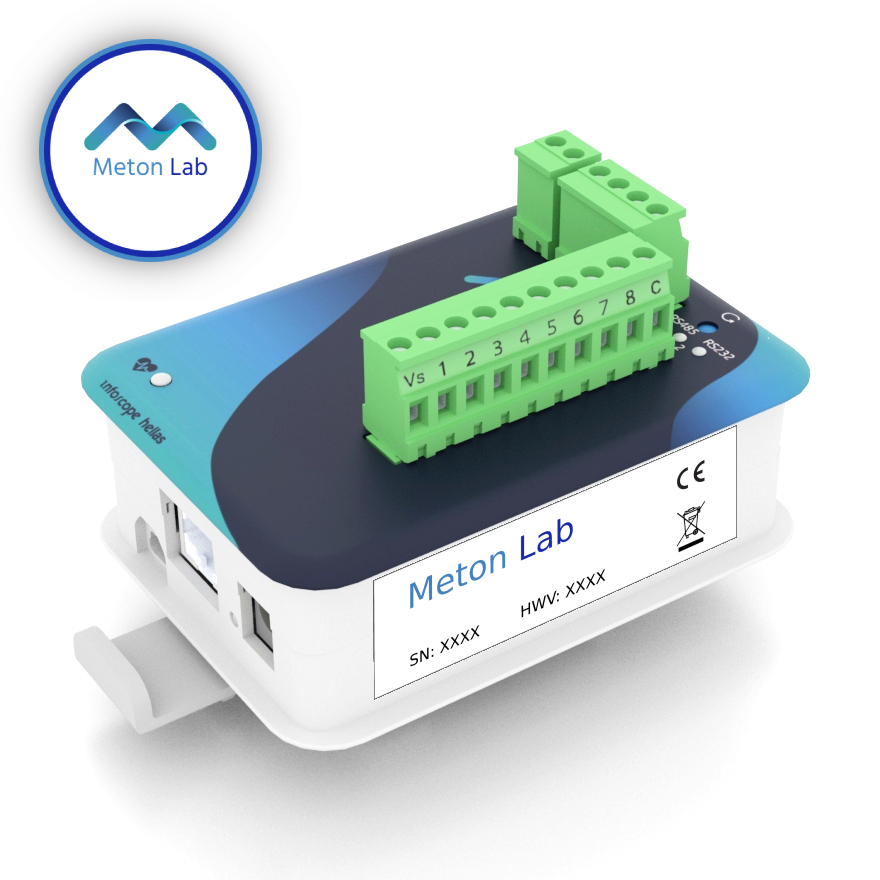

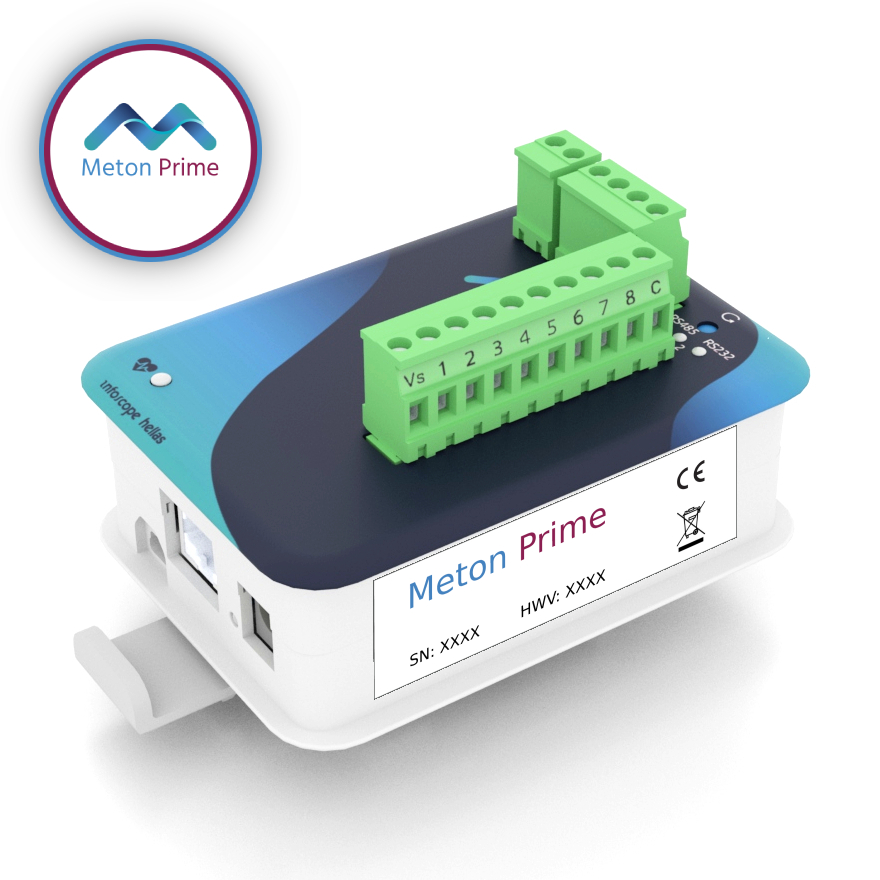

- Collection of analog/digital data from specialized sensors (fluid flow, hydrometry data, conductivity, ethylene concentration, heat pump operation, specialized scales, etc.)

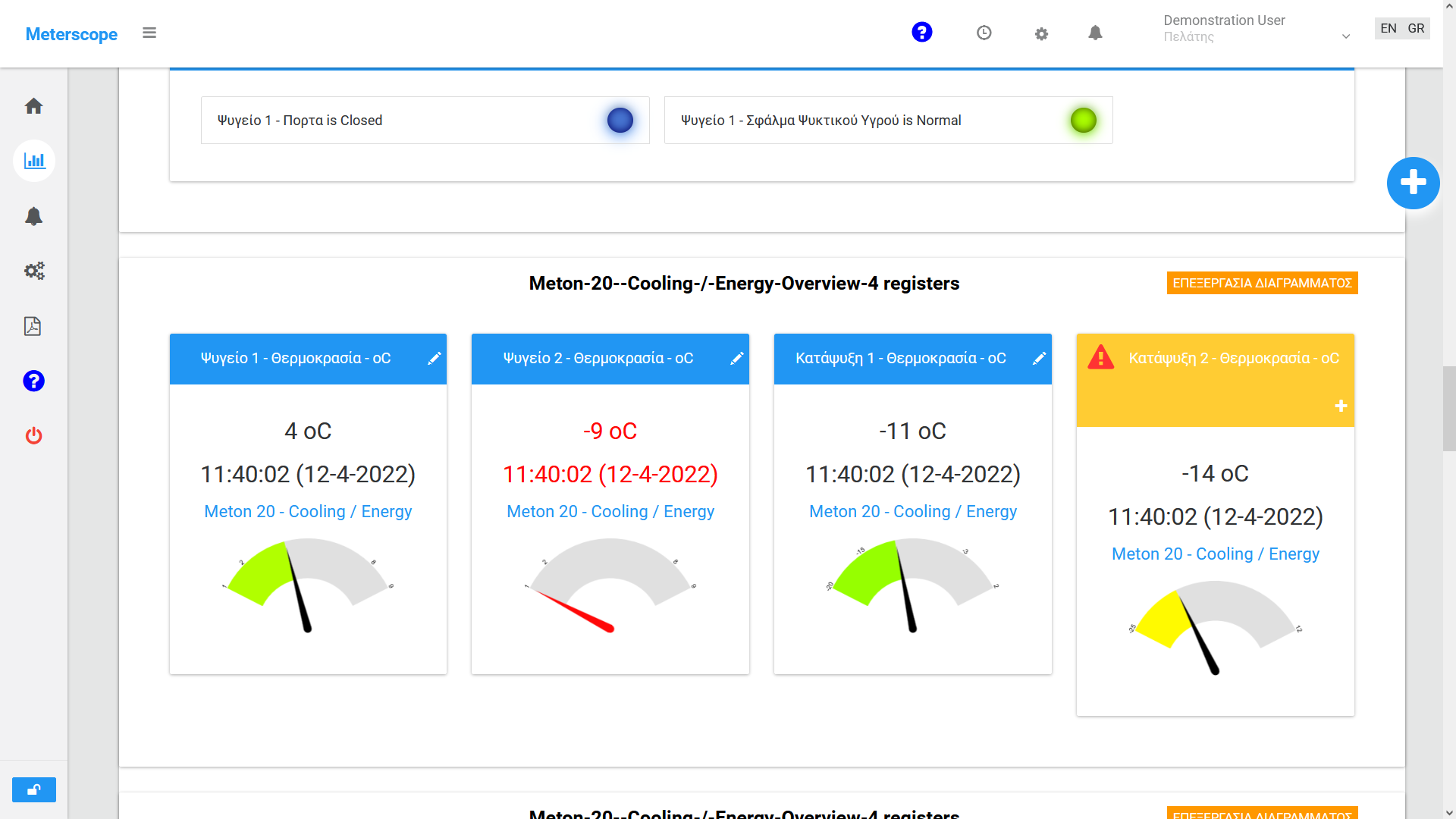

- Recording data from cooling control devices, heating systems, transmitters, cooling towers, boilers, etc. (temperature, humidity, level, pressure, energy consumption, power, voltage/current intensity, operational status of individual components, digital contacts) via industrial communication protocols

- On board sensors for analog and digital inputs

- Integration with a variety of controllers, specialized devices, and PLCs

- Proper operation rules & notification configuration through extremely user friendly interface (on a personal computer or tablet)

- Alarm notification even when the data logger itself is not working / communicating properly

- Data are available online: Very easy data export, event log, realtime overview by any pc/tablet (cloud login)

Immediate Benefits

- Saves time - manual logging no longer necessary

- Expedites HACCP / ISO protocols' compliance

- Temperature (and other) data are easily accessible in case of an unannounced inspection

- Assures that cooling rooms, refrigerators, freezers etc are keeping accurately the temperature set

- Can be connected (through modbus protocol) to device controllers and receive specific data directly from them (e.g. cold room evaporator temperature)

- Supports a large number and wide variety of devices

- Can monitor the energy consumption of each device / floor / sector / building

- Able to also supervise industrial / lab equipment: Machinery, boilers, pasteurizers, generators, super low temperature cooling (e.g. liquid nitrogen tanks etc

- Supervision of mechanical equipment (production machines, boilers, etc.)

- Immediate notification in case of malfunction/damage through e-mail/sms/phonecall, regarding the emergency of the event

Special Features

- Our data logger is preconfigured for you.

- No software installation required

- In case of replacement, a 'twin' device is used to maintain continuity in existing recordings, eliminating the need for account reconfiguration

- Software updates are performed automatically without user interference

- Connection with existing equipment (heat pumps, automation etc)

- Expandable (additional devices, e.g. for energy metering)

- EN 12830:2018 compliance for vulnerable product temperature monitoring

- Automated weekly report for each interconnected device of the equipment, pointing out deviations / pottential malfunction

- Free technical inspection even after the warranty period has expired

- Designed in Greece / Produced in the EU

Full compliance with the EN-12830:2018 standard 'Temperature recording during transport, storage & distribution of temperature-sensitive goods - Tests, performance, suitability' as an end-to-end cloud SaaS system with class IIIb software certification (according to WELMEC 7.2), suitable for storage (S) applications with an accuracy of 0.5 in the measurement range -30...45°C, for temperature recording in temperature-sensitive products.

Contact us for more information, demo account or quotation!