In the food industry, strict temperature control is essential to ensure food safety and compliance with regulatory standards. For professionals managing restaurants, supermarkets, or any food-handling operation, understanding the legal requirements for temperature monitoring is crucial.

Greek law, aligned with EU regulations, mandates specific temperature controls to prevent spoilage and protect consumer health. This article highlights key temperature monitoring obligations and the relevant laws that regulate them.

Legal Framework Governing Temperature Monitoring

The history of food safety legislation in Greece has evolved significantly since the 1960s, starting with the Food and Beverage Code, which was established following Ministerial Decision 299/1968 and came into effect in 1971.

The country’s integration into the European Union in 1981 prompted a gradual alignment with EU directives, leading further evolution of the Food and Beverage Code in order to meet the EU regulations and the introduction of Law 2741/1999 that established the ΕΦΕΤ (Hellenic Food Authority) and focused on improving hygiene and risk management across food operations.

Today, the legislative framework governing food safety in Greece largely comprises updated European Regulations (EC) 178/2002, 882/2004, 852/2004, 853/2004, and 854/2004, alongside the Food & Drinks Code and national Law 4235/2014.

European Regulations

European Union Regulations are legal instruments defined in Article 288 of the Treaty on the Functioning of the European Union. They have general applicability, are binding in their entirety, and are directly applicable in all EU member states.

The following continuously updated* regulations form the basis of the legislative framework for food safety and serve as references for other provisions and procedures (e.g., HACCP):

- Regulation (EC) 852/2004: Covers general hygiene rules for all food-related businesses, ensuring safe food handling throughout the production, transportation, and distribution processes, including strict temperature limits.

- Regulation (EC) 178/2002: Establishes general principles and requirements of food law, the European Food Safety Authority (EFSA), and procedures for food safety matters. It is the cornerstone of the legislative framework, ensuring a high level of protection for human health and consumer interests.

-

Regulation (EC) 853/2004: Lays down specific hygiene rules for foods of animal origin. It includes temperature control requirements, specifying maximum permissible temperatures for products, e.g.**:

- Fresh Meat: Maximum 7°C

- Minced Meat: Maximum 2°C

- Fresh Fish: Temperature 0-2°C

- Dairy Products: Temperature up to 6°C

- Frozen Foods: Temperature up to -18°C

- Regulation (EC) 854/2004: Defines special provisions for organizing official controls on products of animal origin intended for human consumption, including compliance with temperature requirements during production and distribution.

- Regulation (EC) 882/2004: Focuses on official controls carried out by authorities to ensure compliance with food and feed law, including penalties for non-compliance.

*For example, Regulation (EC) 178/2002 was last updated on July 1, 2024. Similarly, the latest versions of Regulations 852/2004 and 853/2004 were updated on March 24, 2021, and November 9, 2024, respectively. Businesses must refer to these versions to stay informed on the current legislative framework.

**The temperature limits mentioned are indicative. For example, the maximum permissible temperature for dairy or frozen products is specified based on the type of product and the stage of the process. For exact values per category, one must consult the HACCP standard being followed, which must be aligned with the latest version of the corresponding European regulation.

Food & Drinks Code

The Food & Drinks Code serves as a detailed reference tailored to Greece's specific needs and conditions. It provides more detailed and practical guidance than European regulations, addressing national specifics or clarifying ambiguities in the EU framework. It ensures compliance with both EU directives and additional Greek requirements, filling gaps left by non-specific provisions in European law.

Law 4235/2014

Law 4235/2014 defines EFET's responsibilities for enforcing compliance with food safety standards. It also specifies administrative measures, procedures, and sanctions applied in cases of non-compliance. EFET inspects facilities for compliance with Greek and European regulations, with established processes and procedures. Non-compliance can lead to strict penalties.

Mandatory Temperature Monitoring Practices

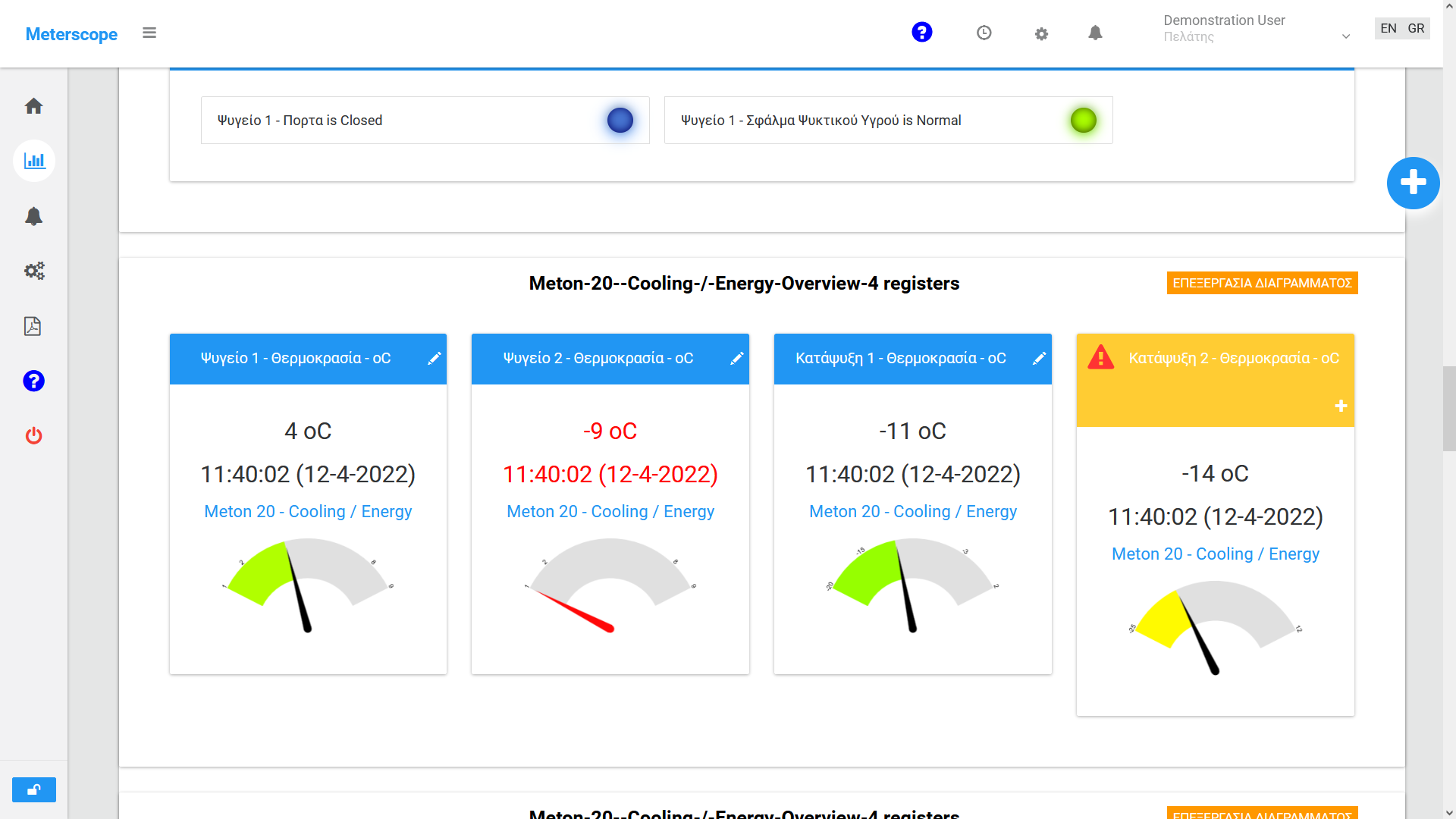

For all food businesses handling perishable items, temperature monitoring is legally mandated to ensure compliance with established limits. This can be achieved through:

-

Automated Temperature Monitoring Systems: These systems provide continuous temperature tracking with alerts for deviations, enabling quick response to temperature fluctuations.

-

Manual Temperature Logging: For businesses without automated systems, daily or scheduled manual logging is acceptable. However, this method requires consistent and accurate record-keeping, as these logs may be reviewed during inspections.

The Role of HACCP in Ensuring Compliance

The implementation of an HACCP (Hazard Analysis and Critical Control Points) system is one of the most effective ways to ensure compliance with temperature control regulations. HACCP identifies critical control points, such as cooling or cooking temperatures where deviations can compromise food safety, and describes monitoring techniques, corrective actions, and documentation protocols.

HACCP systems incorporate specifications based on legal standards, such as the EU regulations mentioned above. For example, for temperature control, HACCP references Regulation (EC) 853/2004, which sets specific limits for meat, fish, and dairy products. Additionally, the Food & Drinks Code may provide supplementary context or clarifications specific to Greek businesses.

By establishing clear temperature limits, continuous monitoring, and preventive measures, HACCP helps businesses integrate legal requirements into their daily operations. Furthermore, required documentation facilitates compliance verification during EFET inspections.

Types of Businesses Subject to Temperature Monitoring

Temperature monitoring is legally required for a range of food-related operations, including but not limited to:

-

Food Production Facilities: Businesses like slaughterhouses, dairy plants, fish processing units, and bakeries that require refrigeration for production or storage.

-

Food Retail Businesses: Supermarkets, butchers, fishmongers, and dairy shops selling perishable goods like fresh meat, fish, or milk.

-

Hospitality and Catering Services: Restaurants, hotels, and cafes that store or prepare food needing strict temperature controls.

-

Food Transportation Services: Companies involved in transporting perishable goods, utilizing cold chain logistics.

-

Food Storage Facilities: Cold storage units managing frozen, chilled, or fresh food for preservation and distribution.

Dealing with Temperature Deviations

Short-term deviations are generally tolerated if they do not compromise food safety. For instance, minor temperature increases during loading or unloading may be acceptable if corrected quickly. However, extended deviations must be documented, with corrective actions taken to prevent spoilage or contamination. HACCP plans play a vital role here, as they outline acceptable tolerances and establish protocols for handling deviations.

Consequences of Non-Compliance

ΕΦΕΤ regularly inspects food businesses to ensure compliance with temperature standards. Failure to meet these standards can result in penalties as per National Law 4235/2014, including fines, product disposal, and, in severe cases, temporary closure or criminal charges for repeated violations.

Maintaining accurate records of temperature monitoring is essential, not only to demonstrate compliance during inspections but also to protect businesses from liability in the event of consumer complaints or foodborne illness claims.

Conclusion

Strict temperature monitoring is fundamental to food safety in Greece. Compliance with Law 4235/2014, the relevant EU regulations and the Food & Drinks Code is mandatory, with EFET overseeing their implementation.

Through HACCP systems, which ensure a cohesive approach to implementing necessary procedures such as temperature monitoring, businesses can achieve food safety, legal compliance, and protect their credibility.