Recording of energy, temperature, and operating data from refrigerators, freezers, and cold rooms in hotel businesses

Meterscope is a monitoring and data-collection system for equipment. It is supported by a range of devices with multiple capabilities, specifically adapted to the needs of various sectors and applications

Food Safety

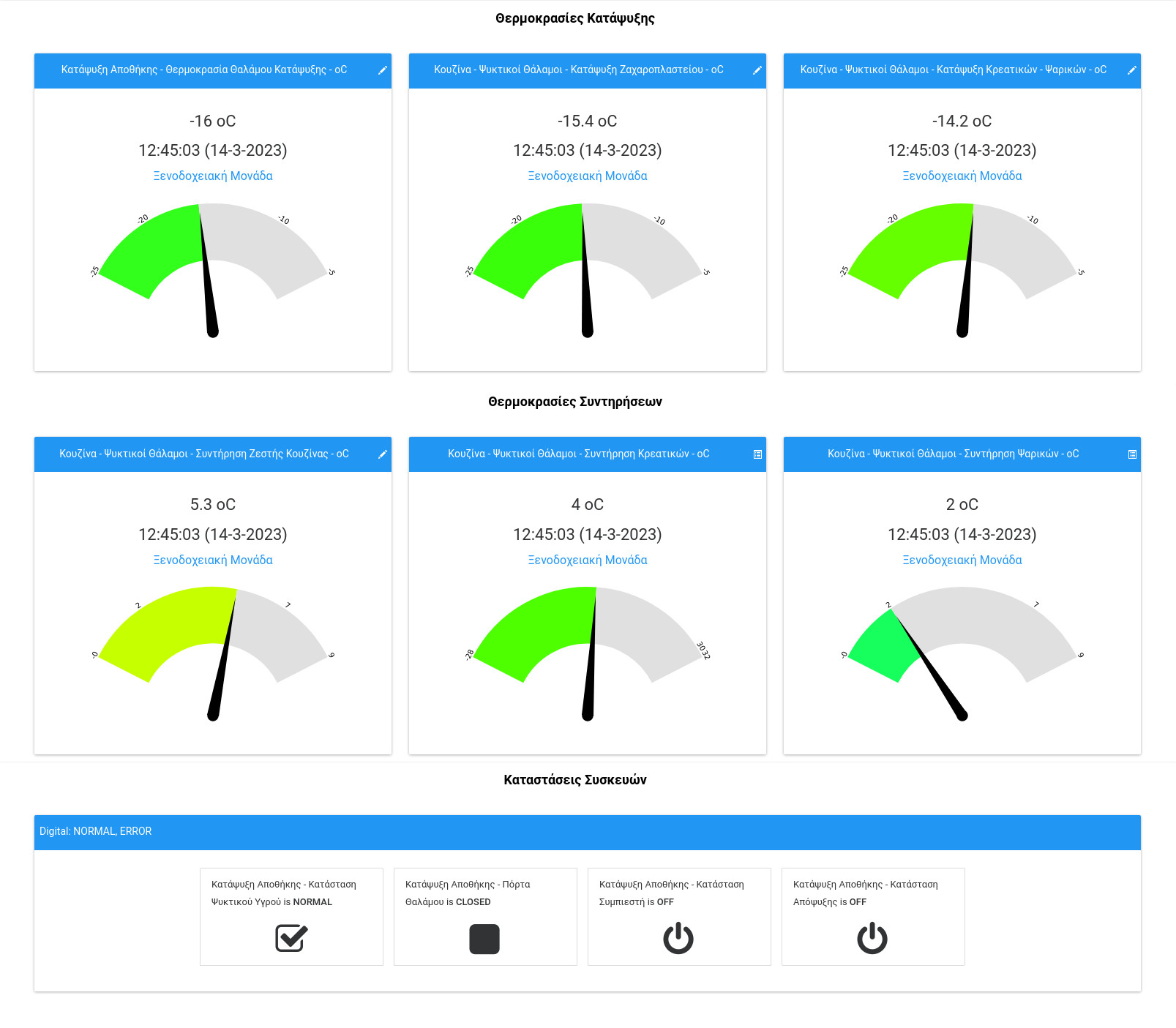

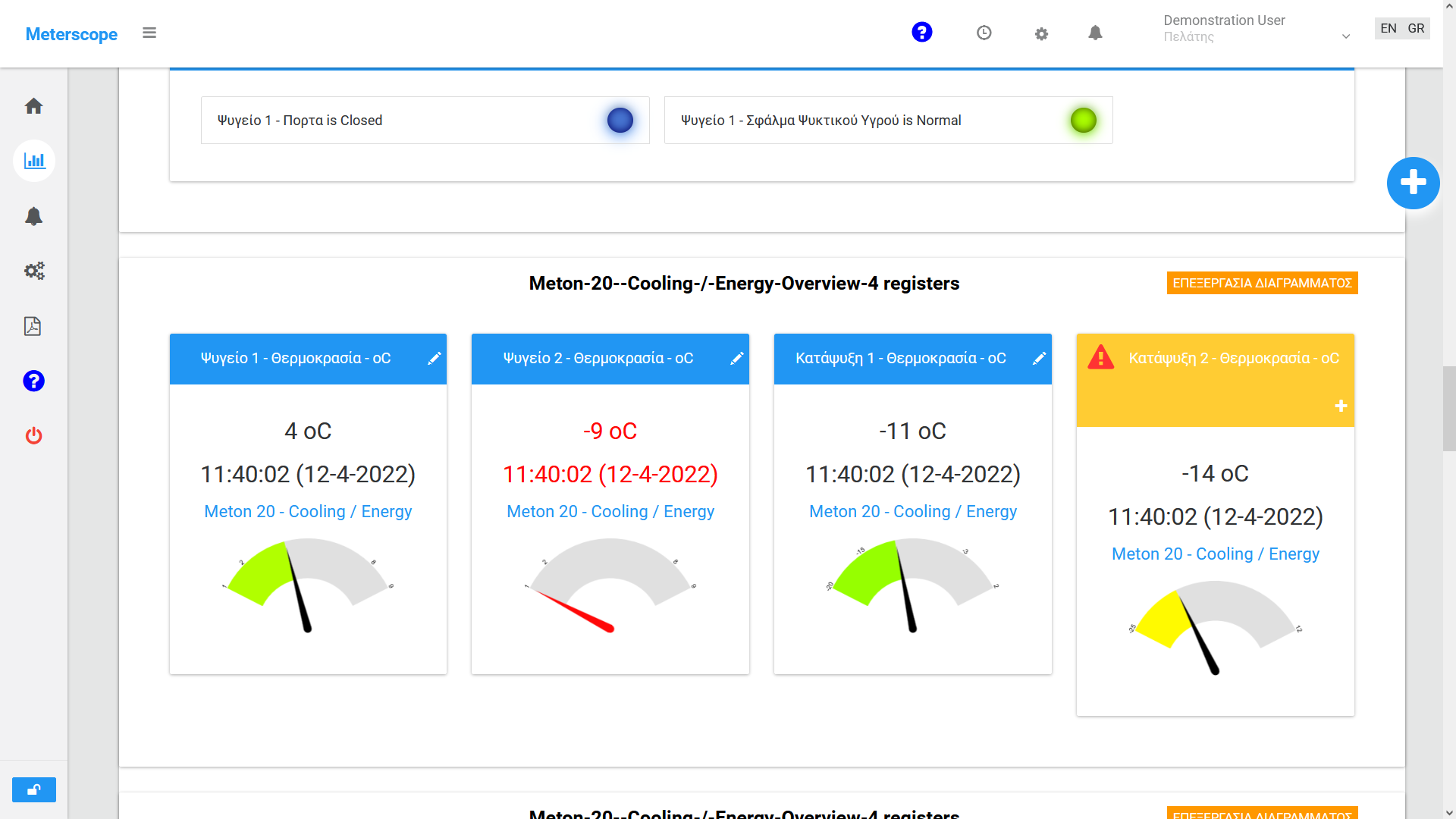

Temperature & operating data logging for refrigerators, freezers, and cold storage rooms

Easy Installation

Centralized data management, wireless sensors for coverage of hard-to-reach areas

After completing installations in major hotel chains, we are able to present the specialized and standardized solution we provide for data logging in hotel units, with specific proposals and solutions for each monitoring point.

Management of large facilities / organizations

Facilitation of ISO 22000 / HACCP procedures, centralized and localized supervision of each facility with different user roles (manager, technical service, chef, etc.)

Expansion to energy & water

Recording of electrical energy, heat pumps, sub-metering of loads, water metering, domestic hot water temperature control, pool chlorine measurement / ISO 50001, 14001

Already installed in more than 500 businesses

Features & Benefits

-

Time savings by eliminating manual record-keeping.

-

Simplification of HACCP / ISO procedures.

-

Immediate and easy extraction of logging files during audits/inspections.

-

Alert notifications in case of malfunction via email / SMS / phone call, depending on severity.

-

Automatic weekly report showing the average operating values of each connected device for early detection of deviations/malfunctions.

-

Ability to retrieve data directly from refrigerator/chamber controllers, without installing sensors on each unit:

-

Temperature logging / door status.

-

Logging of additional information (evaporator data, defrost cycles, alarms, fan operation, digital inputs, etc.).

-

-

Customization to fully align with the company’s ISO processes:

-

Naming and grouping of monitoring points.

-

Event management & prioritization, corrective actions.

-

Report exporting.

-

Different user roles (technical service, Chef–Maître, F&B, management / quality department) for targeted supervision with customized settings.

-

-

Additional logging & specialized features:

-

Proper domestic hot water temperature — safe pool water chlorination.

-

Monitoring of sub-energy consumption — heat pump performance supervision / ISO 50001.

-

Carbon footprint calculation and visualization of equivalent CO₂ emissions / ISO 14001.

-

Why Us

-

Tailored solutions from a specialized team of engineers with extensive experience in Greece and Europe.

-

Extensive partner network & high-quality customer support.

-

Collaboration with top sensor manufacturers.

-

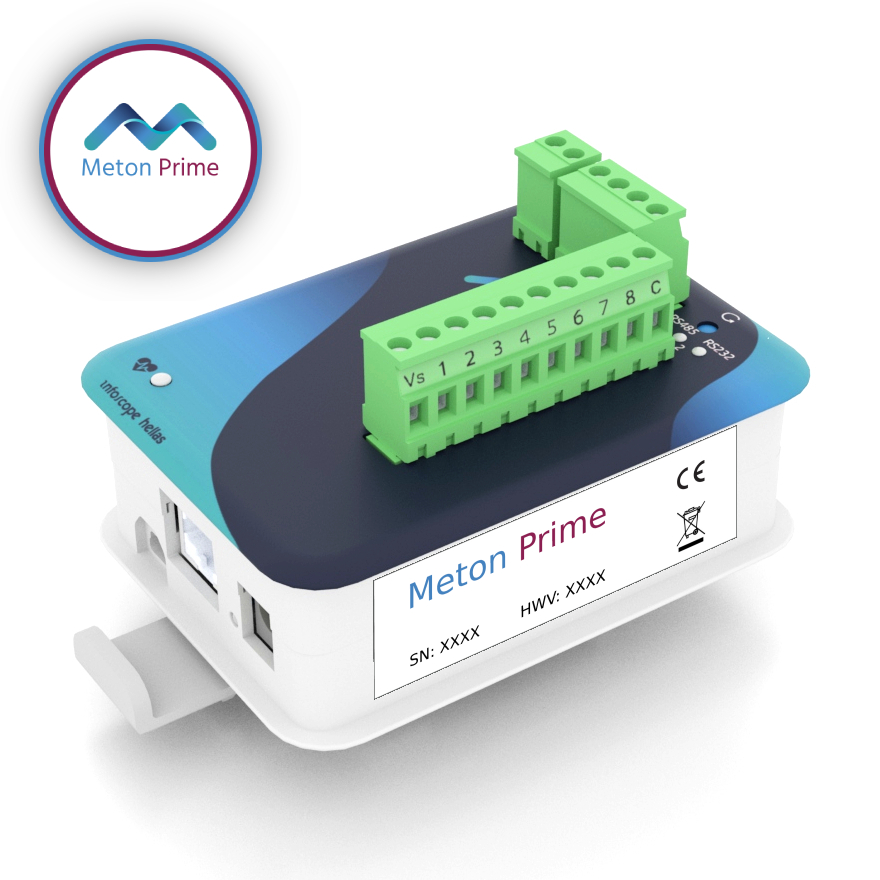

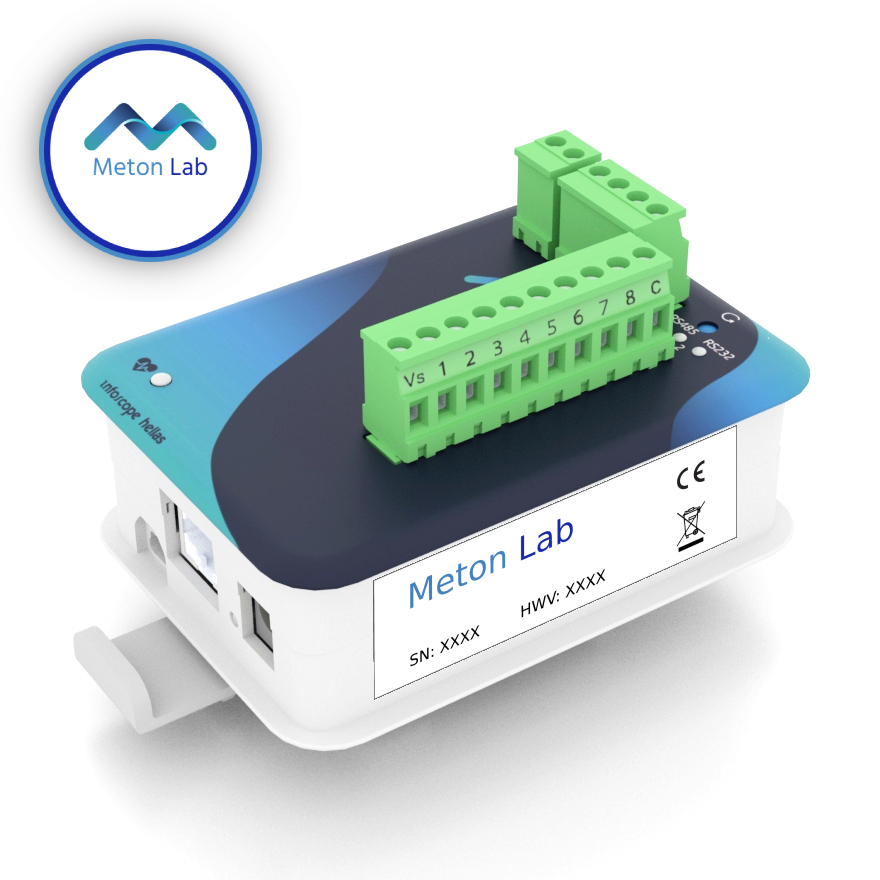

Easy installation through support of multiple communication protocols — flexible choice of wireless or wired connections for each measurement point.

-

One logging unit per facility for greater reliability and easier management.

-

The system is delivered pre-configured; no on-site software installation or configuration required — all updates occur automatically.

-

Advanced configuration tools to prevent false alarms

-

All installations available under the same account.

-

24/7 monitoring through the Meterscope with notifications even in case of device malfunction or power outage

-

Subscription service with clear pricing, free support & updates.

-

In case of replacement, a “twin” device is used to maintain continuity of existing logs without reconfiguration.

-

Free technical inspection even after warranty expiration, with free shipping throughout Greece using our pickup service.

-

Compliance with EN 12830:2018 for temperature logging in sensitive goods.

-

Designed in Greece & manufactured in the EU.

Specialized & additional features

Wireless temperature / humidity monitoring & equipment connectivity

Easy installation with reasonable cost in large/multi-story buildings using Meton Sense – Wireless AddOn or Meton Connect – Wireless AddOn and long-range wireless sensors with industrial communication protocol and 14-year battery life.

Combines the benefits, robustness, and reliability of centralized data collection with the flexibility of wireless sensors, which can be installed without specialized technicians.

Counters, Upright Refrigerators, Display Cases, Freezers

-

Wired or wireless probe-type sensors installed in the refrigerated section through the provided opening, minimizing loss of usable storage space.

-

Wireless sensors installed directly inside the refrigerated area for easy placement.

Cold Rooms – Chillers / Freezers

-

Monitoring of temperature via long-range wireless sensors (covering multiple floors across an entire building block).

-

Option for direct RS485 connection to the cold-room controller for reliable acquisition of additional data (door, defrost process, etc.) and full alignment with the displayed temperature.

-

Capability to extend logging to humidity, digital signals, CO₂, etc.

Other Equipment

-

Energy consumption – Load monitoring and management.

-

Heat pumps – Performance and automation logic.

-

Domestic hot water temperature – Control and automation scenarios.

-

Pool water chlorine concentration – Monitoring and automation scenarios.

Brief presentation of all the available gateways/data loggers & features

Contact us for more information, demo account or invoice!