Differentiating Real Events from Unnecessary Alarms

A problem that all recording systems often face is the inability to distinguish when an alarm is real and requires immediate intervention and when the notification for that event is unnecessary.

Every business has its own peculiarities, and often adhering to a strict protocol results in a large number of events, making the monitoring of recording points impractical.

Apart from the inconvenience it causes, a large number of security notifications can mean that an event accompanied by real damage is more likely to go unnoticed.

A device may be normally out of operation at times, and a violation of the normal operating limits may not be a problem when the storage area is empty of products.

The professional's daily routine does not follow a simple linear rule that "if the normal operating limits are violated, an alarm must be triggered." And there is no need to burden it with unnecessary alarms, for fear that it will not be notified of the real ones.

Identifying Problematic Areas

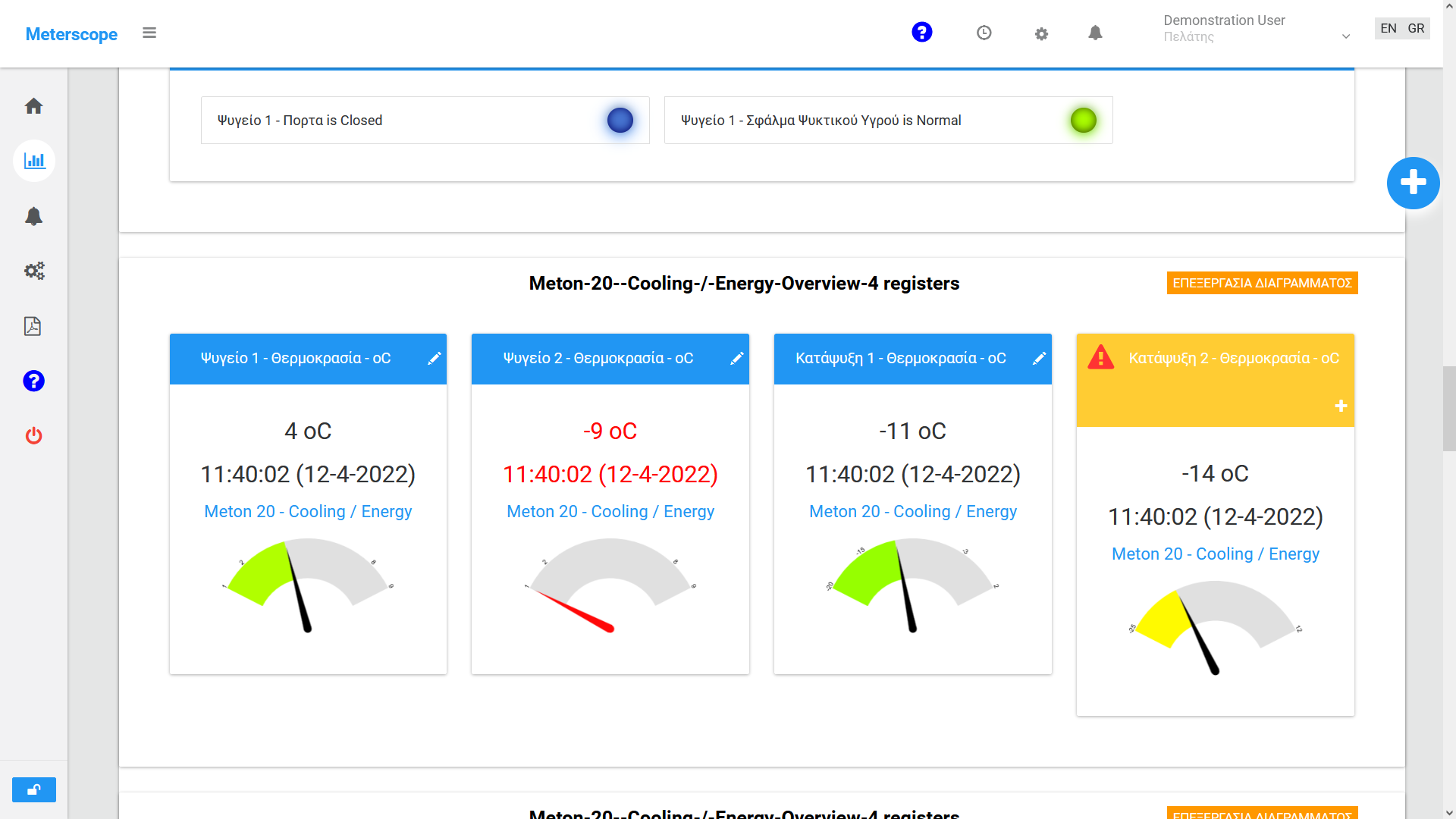

An important step in addressing the high volume of events and notifications is identifying the points that generate the majority of them.

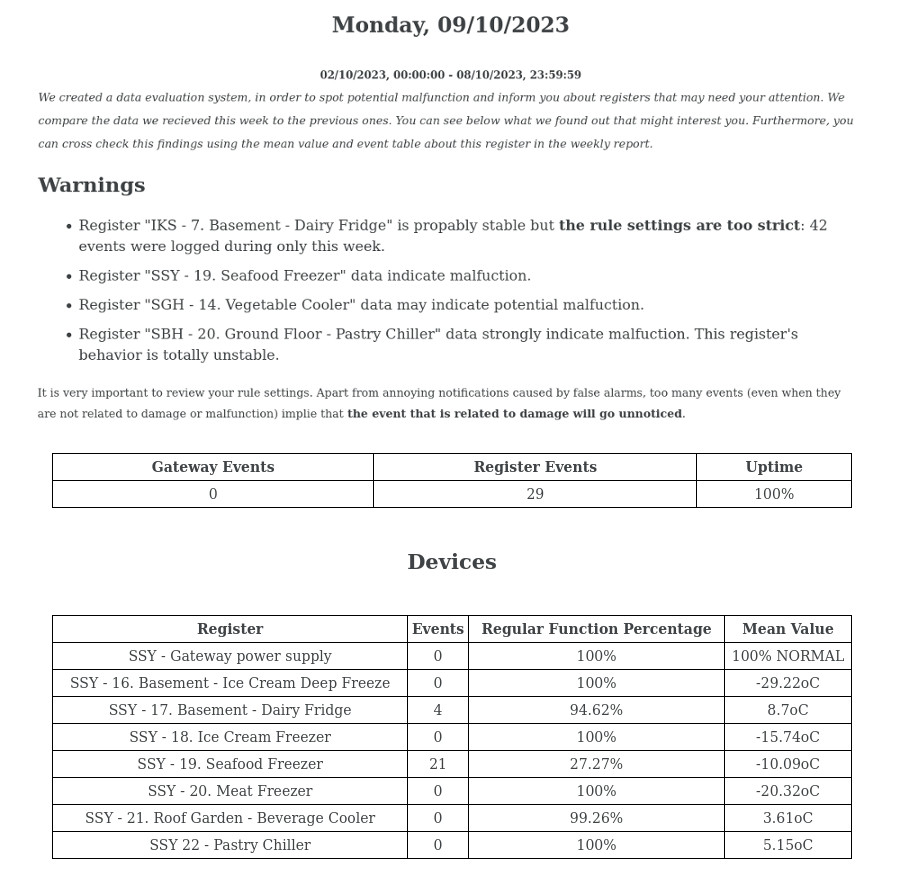

The automatic weekly report sent via email every Monday morning provides a detailed overview of the average performance of each device and highlights the points that exhibit the greatest instability and/or frequently violate normal operating limits.

Of course, the event file and their distribution per point are available at any time on each user's Meterscope account. Additionally, the graphical representation of the recording file of problematic points can be helpful.

Optimizing Data Recording & Sensor Placement

The first and fundamental approach to the problem is to control the position and performance of the sensors.

The placement of the sensors may play a significant role in recording temperatures that exhibit high instability or deviate from the actual operating temperature of a device. For example, positioning a sensor next to the door of a chamber can lead to very rapid and significant temperature data changes, while placing it in a location likely to encounter ice may result in measurements that do not correspond to the actual operating conditions of the device.

Placing the sensor at a point where the recorded temperature is more representative of the equipment's operation (typically near the device controller's sensor) is the ideal solution.

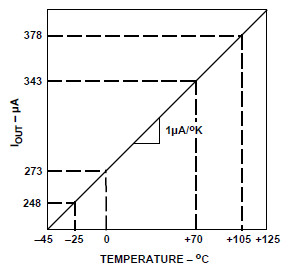

For the most demanding applications, there is the option of using MB1-TXs sensors, which provide reliable temperature recording at an acceptable cost, even with long cables, without being affected by electromagnetic noise and deviations introduced over long distances.

Finally, there is (technically) the possibility of placing the temperature sensor in a glycol container to better simulate the temperature of the products and avoid abrupt changes.

Configuration of Proper Operation Rules

Meterscope provides a range of configuration options for proper operation rules to avoid unnecessary/excessive alarms:

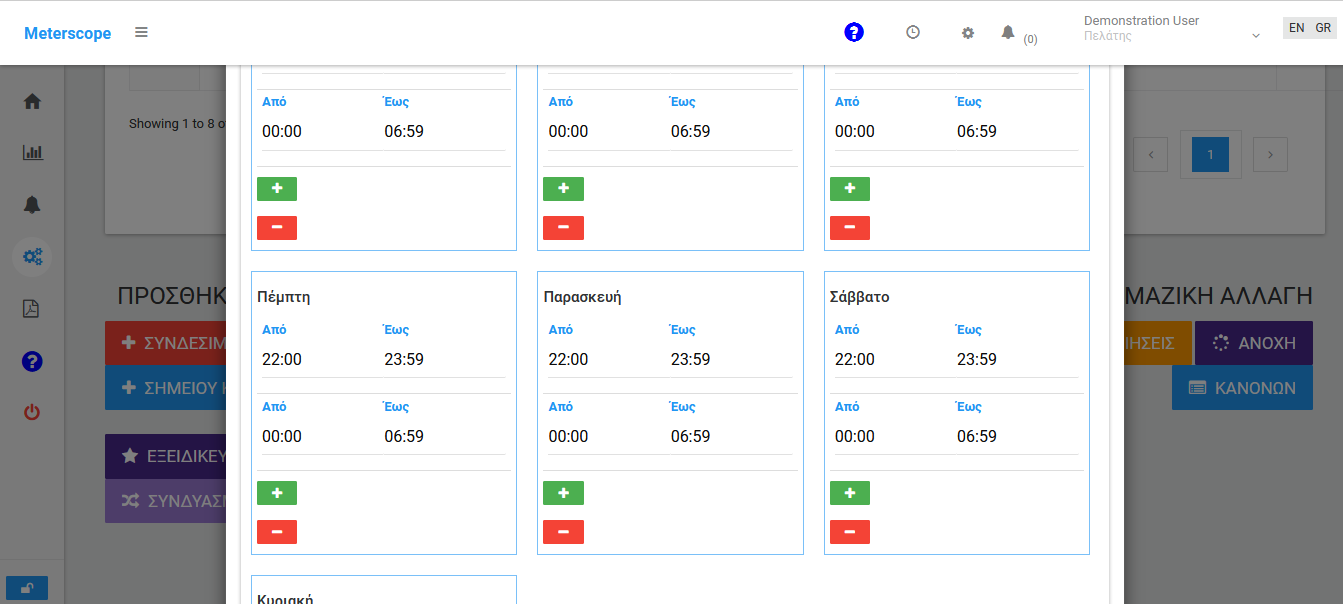

- Schedule of notifications: Events occurring at specific times, resulting from known and inevitable processes, can be recorded in the event log without simultaneous notification.

- Sets of operation rules with graded strictness: You have the option to choose sets of operation rules with very strict limits - in line with relevant HACCP/ISO standards - to record events in the respective log file. Additionally, there are separate sets of rules with less strict limits that imply the possibility of damage, along with simultaneous email, SMS, and/or phone notifications, depending on the deviation from proper equipment operation or user preferences.

Complex & Specialized Configuration

Specialization of Proper Operation Conditions

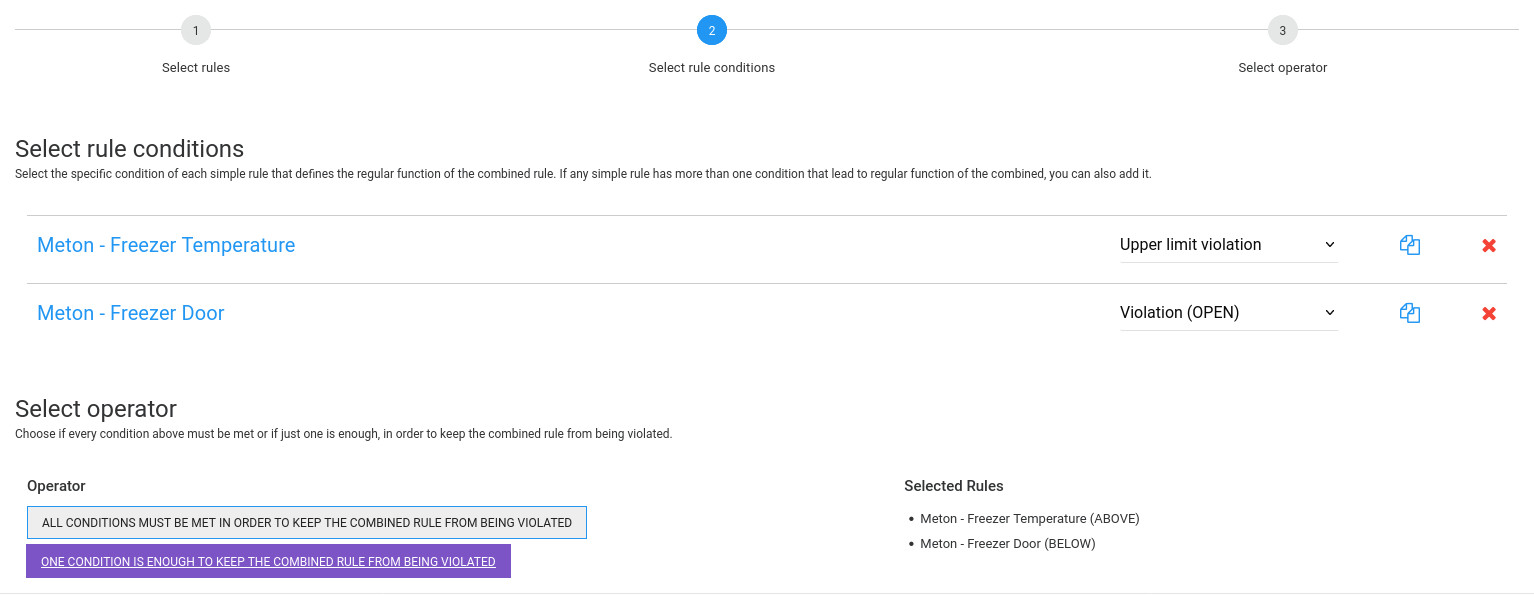

In cases where the complexity of processes cannot be covered by simple rules of proper operation, there is the option for complex configuration by introducing a combination of rules.

With the proper setup, Meterscope is capable of measuring all necessary parameters.

The user can now select the specialized conditions under which an active event will be created, and they will receive a notification.

This way, it prevents notifications from empty refrigerators that violated temperature limits, devices that remain out of operation due to the season, or even entire sections of the business that operate on specific days or hours.

Combination of Operating Rules

The process of creating a complex rule is easy and straightforward for experienced users.

- Define the operating rules (temperature, device status, open or closed door, energy consumption, weight, CO2 concentration) and select that these rules only operate as part of a complex rule.

- Choose the combination that indicates a malfunction (temperature limit violation while the device should be operational and contains products) and the notification you wish to receive.

- It can also choose scheduling to avoid receiving notifications for cases when someone is on-site checking the status.

The recording system should make the professional's life easier and not complicate it without a good reason.

Meterscope moves in this direction and continuously evolves to combine safety with user-friendliness, without unnecessary side effects.

See also

Temperature Data Logger - Meton Sense

Τemperature / humididty / digital input data logger supporting 8 on board inputs and expansion modules

- Cold rooms, refrigerators, curing chambers, kettles, ovens and custom equipment temperature

- Great variety of sensors (RTDs: Pt100, Pt1000, 2 or 3 wire, Thermistors: NTC or PTC, Thermocouple K, J, generic signal transmitters 4...20mA, 0-10V) that can cover an extremely wide temperature range (-200oC, +1800oC)

- Digital input (normally open/normally closed, function) & outputs (relay, siren, light)

Wireless Edition Extra Features

- Wireless sensors allowing for extra long battery life (up to 14 years!) &

- Industrial communication protocol, providing strong encryption

- Long range reception, covering whole building blocks / serveral floors in urban area

- Waterproof IP65, polycarbonate cabinet

- Autonomous internet connection (3G Modem) for stand alone installation or fallback handling in case of bad network

- Power supply back up (UPS) for energy autonomy and monitoring under power outage condition

Read more about Meton Sense - Wireless Edition

Device Controllers' Gateway - Meton Connect

Collecting data directly from the interconnected devices' controllers

- Data from interconnected devices that support Modbus / M-Bus protocols

- Temperature and DI (normally open/closed, function) monitoring of cold rooms, refrigerators, freezers and other rooms/devices. Inteconnection with a wide variety of controllers (Dixell, Pego, Eliwell, etc)

- Humidity, level, pressure, weight, fluid flow, energy consumption, custom lab equipment, custom sensors