Fully compliannt with the standard EN-12830:2018 “Temperature recorders for the transport, storage and distribution of temperature sensitive goods” as a cloud SaaS system with software verification level class IIIb (acc. to WELMEC 7.2), suitable for storage applications (S), for temperature recording in temperature sensitive goods.

Culminating the installation of systems in three major hotel chains, each featuring over 50 restaurants and kitchens, we are delighted to introduce our tailored solution for managing temperature records within hotel establishments

Key Advantages

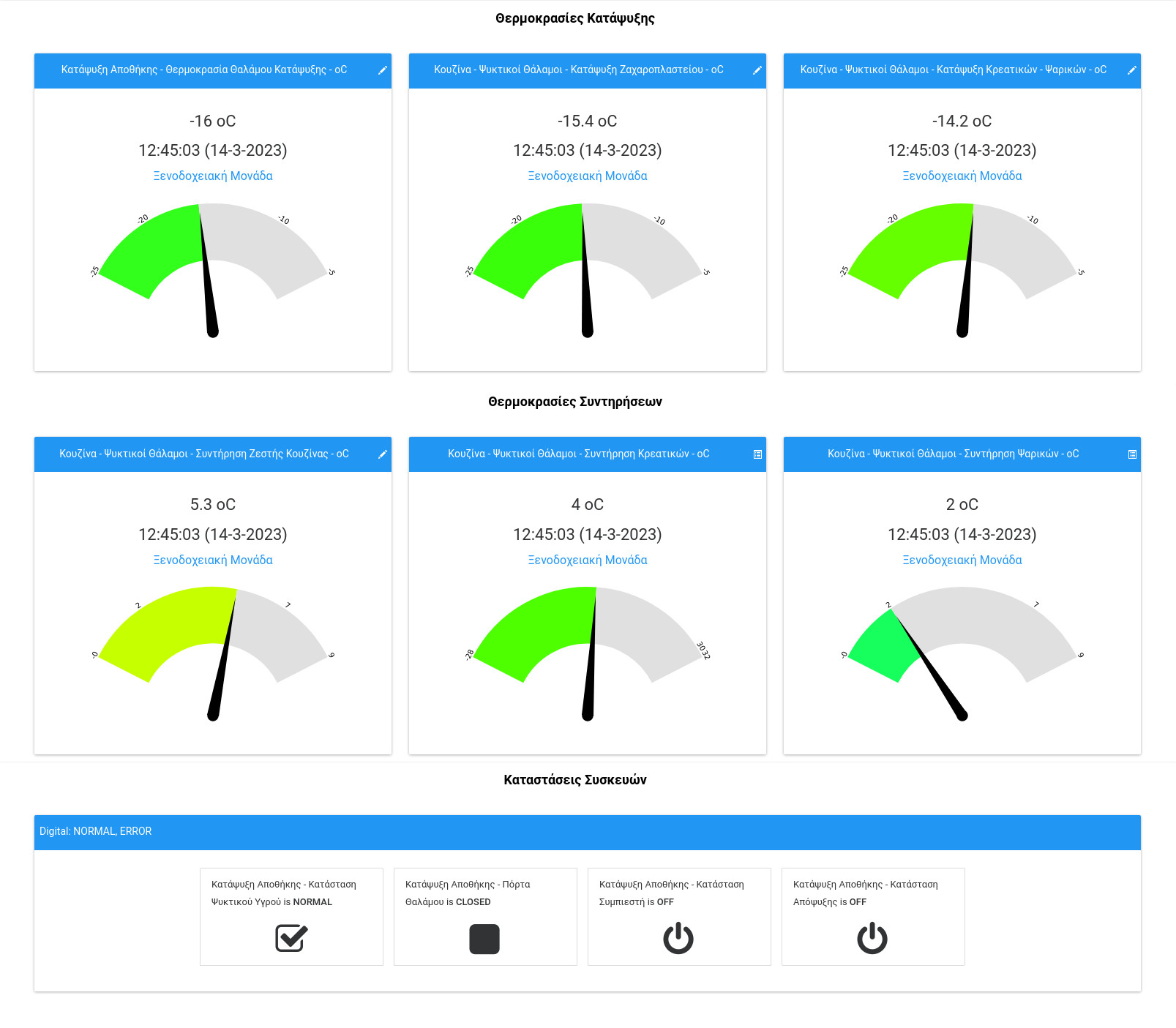

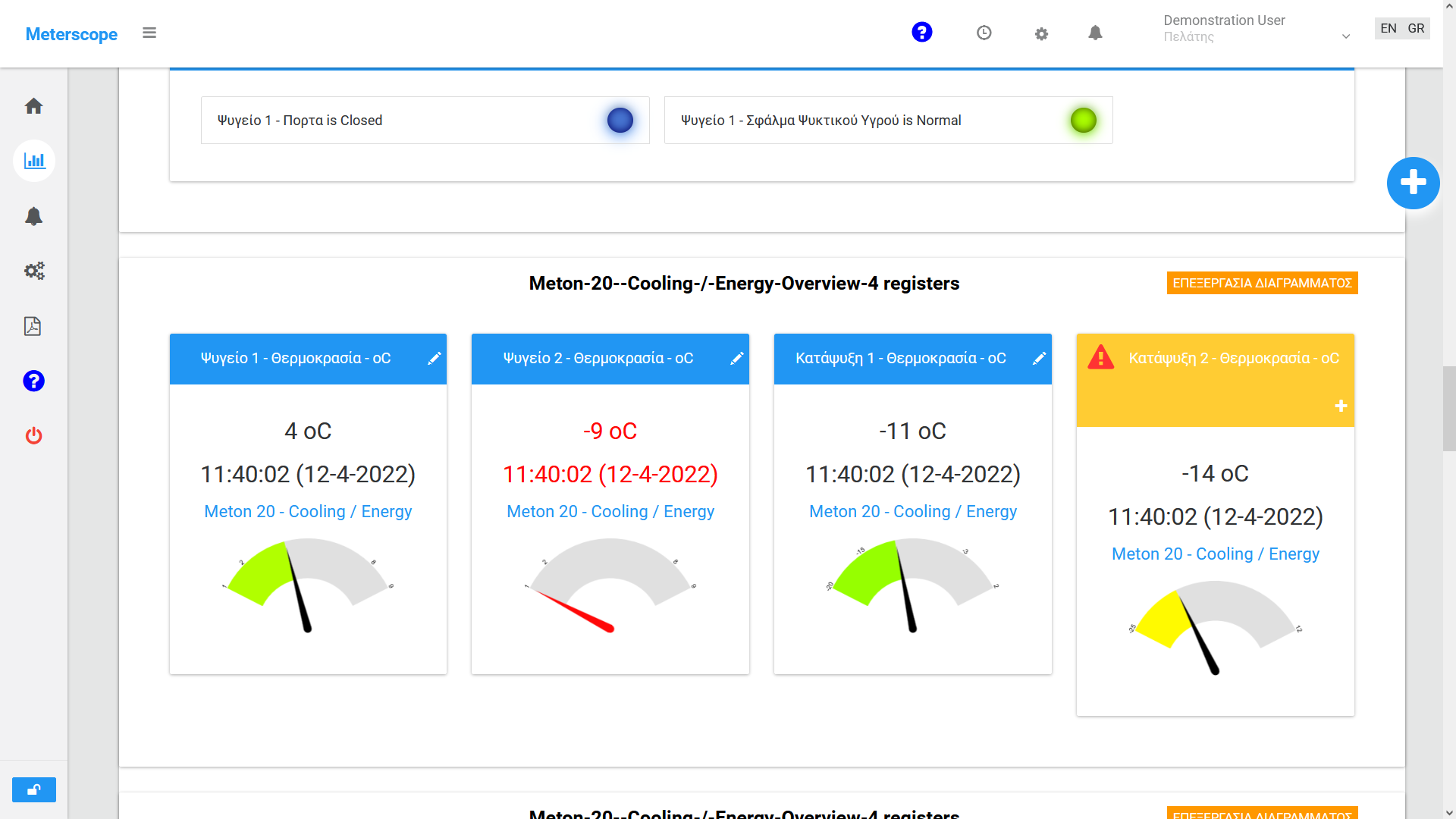

- Centralized data collection for enhanced reliability, efficient management of multiple spaces/buildings, and easy access in a user-friendly environment

- Customized facility monitoring with distinct settings for various roles (technical service, F&B, chef-maitre, quality department, management)

Specialized Features

- Provision of tools tailored to facilitate HACCP procedure compliance / Enhanced customization capabilities for full alignment with ISO 22000 standards.

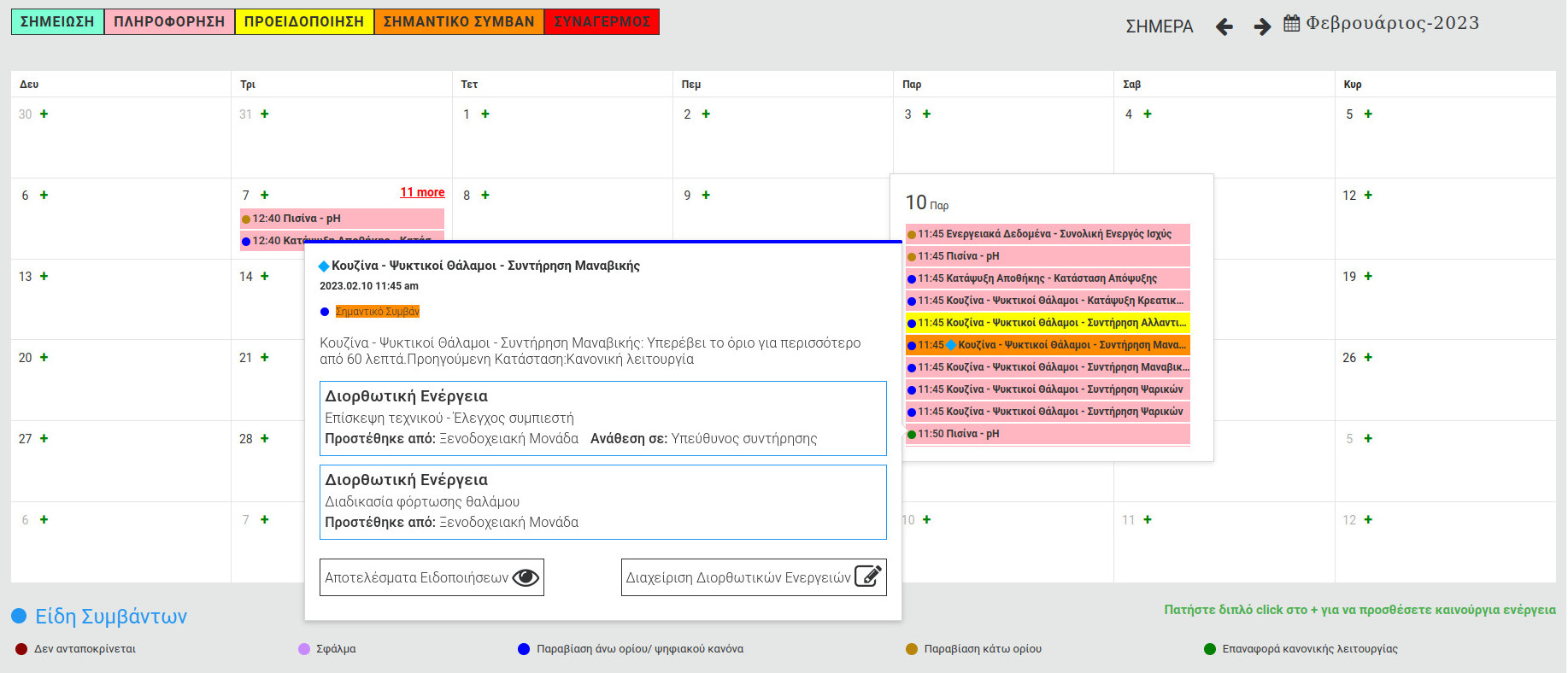

- Event management, corrective actions, and report generation

Immediate Benefits

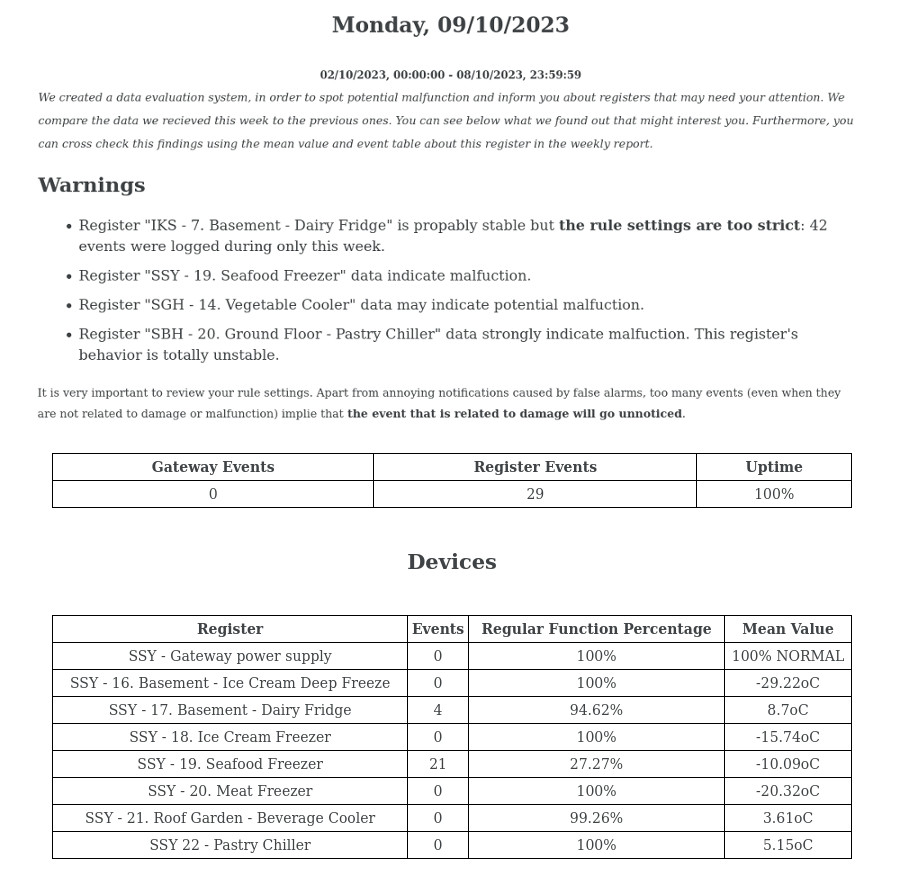

- Time & cost savings during the management of record data required for reliable compliance with HACCP & ISO procedures

- Notifications for damage or malfunction received via email, SMS, or phone call, depending on the severity of the situation

- Customization of rules to prevent false alarms

- Automatic weekly evaluation using average device performance for the detection of anomalies or malfunctions

Additional Capabilities

- Data retrieval from existing equipment (chamber controllers, heat pumps, automation, etc.)

- Expansion with data from new devices (water metering, energy meters) and visualization of energy consumption - ISO 50001

- Calculation of ecological footprint and representation of equivalent carbon dioxide (CO2) emissions - ISO 14001

Can be combined with:

Temperature Data Logger - Meton Sense

Τemperature / humididty / digital input data logger supporting 8 on board inputs and expansion modules

- Cold rooms, refrigerators, curing chambers, kettles, ovens and custom equipment temperature

- Great variety of sensors (RTDs: Pt100, Pt1000, 2 or 3 wire, Thermistors: NTC or PTC, Thermocouple K, J, generic signal transmitters 4...20mA, 0-10V) that can cover an extremely wide temperature range (-200oC, +1800oC)

- Digital input (normally open/normally closed, function) & outputs (relay, siren, light)

Wireless Edition Extra Features

- Wireless sensors allowing for extra long battery life (up to 14 years!) &

- Industrial communication protocol, providing strong encryption

- Long range reception, covering whole building blocks / serveral floors in urban area

- Waterproof IP65, polycarbonate cabinet

- Autonomous internet connection (3G Modem) for stand alone installation or fallback handling in case of bad network

- Power supply back up (UPS) for energy autonomy and monitoring under power outage condition

Read more about Meton Sense - Wireless Edition

Device Controllers' Gateway - Meton Connect

Collecting data directly from the interconnected devices' controllers

- Data from interconnected devices that support Modbus / M-Bus protocols

- Temperature and DI (normally open/closed, function) monitoring of cold rooms, refrigerators, freezers and other rooms/devices. Inteconnection with a wide variety of controllers (Dixell, Pego, Eliwell, etc)

- Humidity, level, pressure, weight, fluid flow, energy consumption, custom lab equipment, custom sensors