In the cooling industry, a substantial technological potential stands ready to redefine the methods of data collection and management.

Meet the Wireless M-Bus protocol—an avenue leading to transformative possibilities. With its roots embedded in the history of utility metering innovation, this protocol offers a new realm of potential for professionals in the cooling sector.

A Glimpse into Untapped Possibilities

Emerging in the early 2000s, the Wireless M-Bus protocol could redefine efficiency in utility meter reading. It has the potential to automate and remotely collect utility data, solving manual challenges. The protocol’s promise lies in streamlining processes, reducing errors, and enhancing accuracy in utility meter readings.

Technical Excellence and Possibilities

The protocol’s success could be attributed to its technical strength. Operating in S Mode (at 868 MHz) and T Mode (at 2.4 GHz), Wireless M-Bus could cater to diverse cooling needs. S Mode, tailored for battery-powered devices, could align with energy-efficient solutions. Meanwhile, T Mode’s potential for higher data rates could suit real-time industrial demands.

The Wireless M-Bus protocol’s promise shines when compared to communication protocols like Wi-Fi:

-

Efficiency Unleashed: Unlike power-hungry Wi-Fi, Wireless M-Bus could excel in efficiency, potentially extending battery life and reducing operational costs—essential for sustainable cooling practices.

-

Dedicated Precision: Potential use of dedicated frequencies could ensure minimal interference and precise data collection. This could overcome Wi-Fi’s interference vulnerabilities, guaranteeing accurate temperature data.

-

Remote Mastery: Wireless M-Bus potential could overcome Wi-Fi's limitations, enabling access to remote temperature data. Even challenging areas could be within reach.

-

Real-time Insights: The potential for real-time data collection could empower swift responses to temperature changes, aiding proactive issue prevention.

-

Enhanced Security: Potential robust encryption and authentication could enhance data security, surpassing Wi-Fi’s potential vulnerabilities.

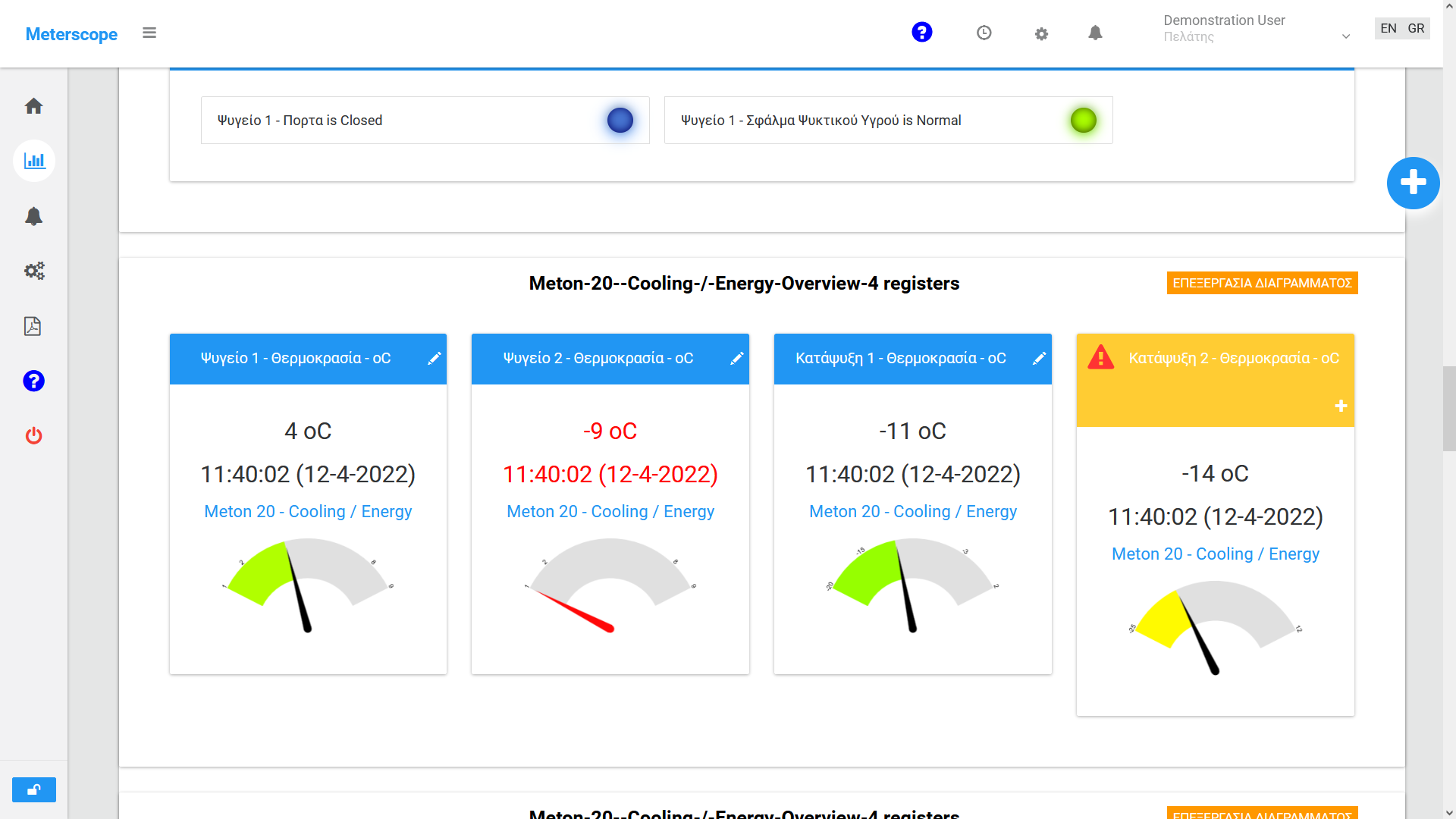

Case Study: Optimizing Cooling with Wireless M-Bus

Imagine a sprawling mall with intricate cooling requirements. Stores, hallways, and common areas demand precise temperature control. Here, Wireless M-Bus potential emerges as an innovation beacon.

Temperature sensors, each equipped with a Wireless M-Bus module, could discreetly dot the mall. They could wirelessly relay data to central collection points. Data concentrators could potentially aggregate and transmit this to a centralized system.

The potential benefits are straightforward:

-

Effortless Monitoring: Remote access to temperature data could replace manual checks, simplifying monitoring for professionals.

-

Proactive Precision: Swift responses to deviations could prevent malfunctions or unusual warmth.

-

Resource Optimization: Redirecting resources from routine checks to vital maintenance could enhance efficiency.

-

Informed Decisions: Over time, amassed data could guide energy-efficient decisions, ultimately reducing costs.

In the journey ahead, Wireless M-Bus potential stands as a catalyst for innovation. With its roots in utility metering, it could redefine cooling practices, combining efficiency, accuracy, and adaptability. Beyond a protocol, it’s a potential gateway to a cooler future.

Wireless Temperature Gateway - Meton Wireless

Wireless Temperature Gateway - Meton Wireless

Plug & play wireless temperature gateway very easy to install

- Monitoring temperature and digital inputs (operational status, door status, etc.) of refrigeration chambers, refrigerators, freezers, product storage areas, and other devices wirelessly.

- Sensors communicate via the industrial wireless mBus protocol for greater reliability and energy saving.

- Autonomous sensors with the ability to be placed even within chambers and a battery life of up to 14 years!

- Data collection from numerous points and easy to expand

Read more about Meton Wireless

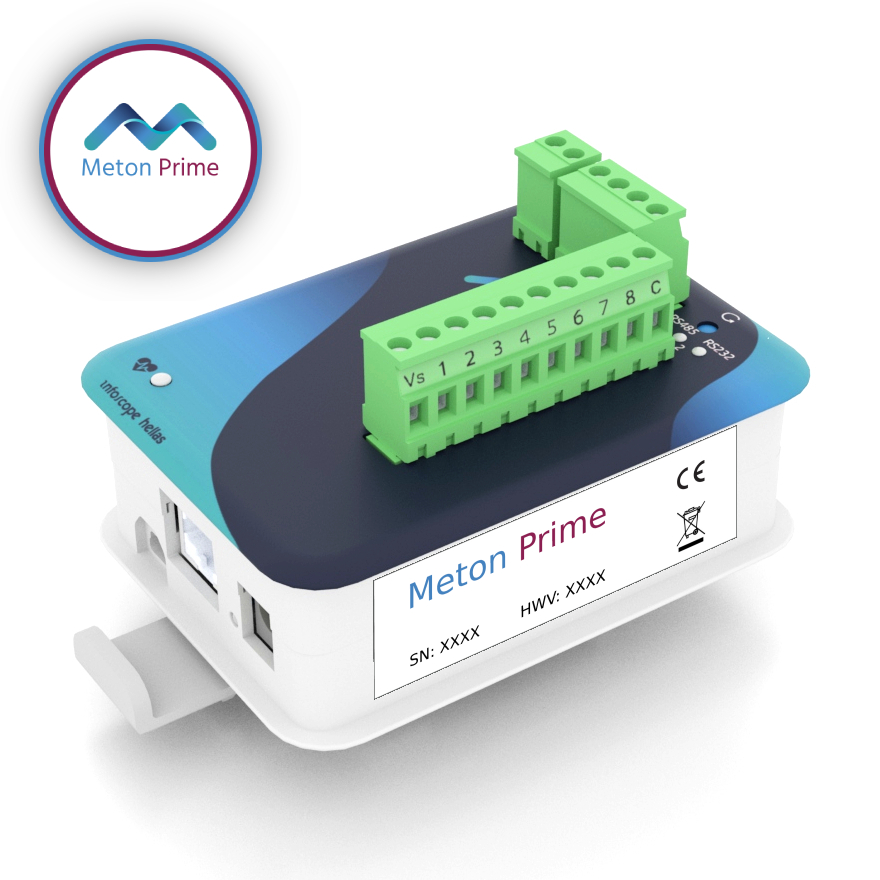

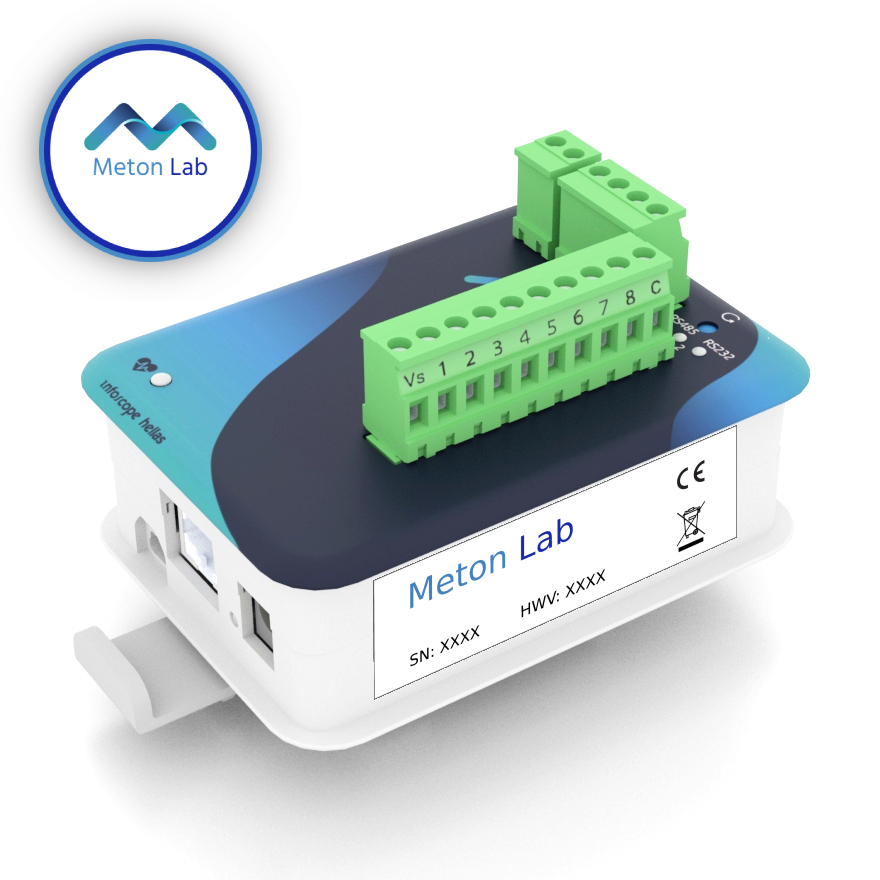

Temperature Data Logger - Meton Sense & Sense Plus

Temperature Data Logger - Meton Sense & Sense Plus

Τemperature / humididty / digital input data logger supporting 8 on board inputs and expansion modules

- Cold rooms, refrigerators, curing chambers, kettles, ovens and custom equipment temperature

- Digital input (normally open/normally closed, function) & outputs (relay, siren, light)

- Extensive sensor options (RTDs: Pt100, Pt1000, 2 or 3 wire, Thermistors: NTC or PTC, Thermocouple K, J, generic signal transmitters 4...20mA, 0-10V) for a vast temperature range (-200°C to +1800°C), high metering accuracy and long-distance coverage with the Meton Sense Plus

Meton Sense - Wireless Addon Extra Features

- Wireless sensors allowing for extra long battery life (up to 14 years!) &

- Industrial communication protocol, providing strong encryption

- Long range reception, covering whole building blocks / serveral floors in urban area

- Waterproof IP65, polycarbonate cabinet

- Autonomous internet connection (3G Modem) for stand alone installation or fallback handling in case of bad network

- Power supply back up (UPS) for energy autonomy and monitoring under power outage condition

Read more about the Wireless Addon of Meton Sense