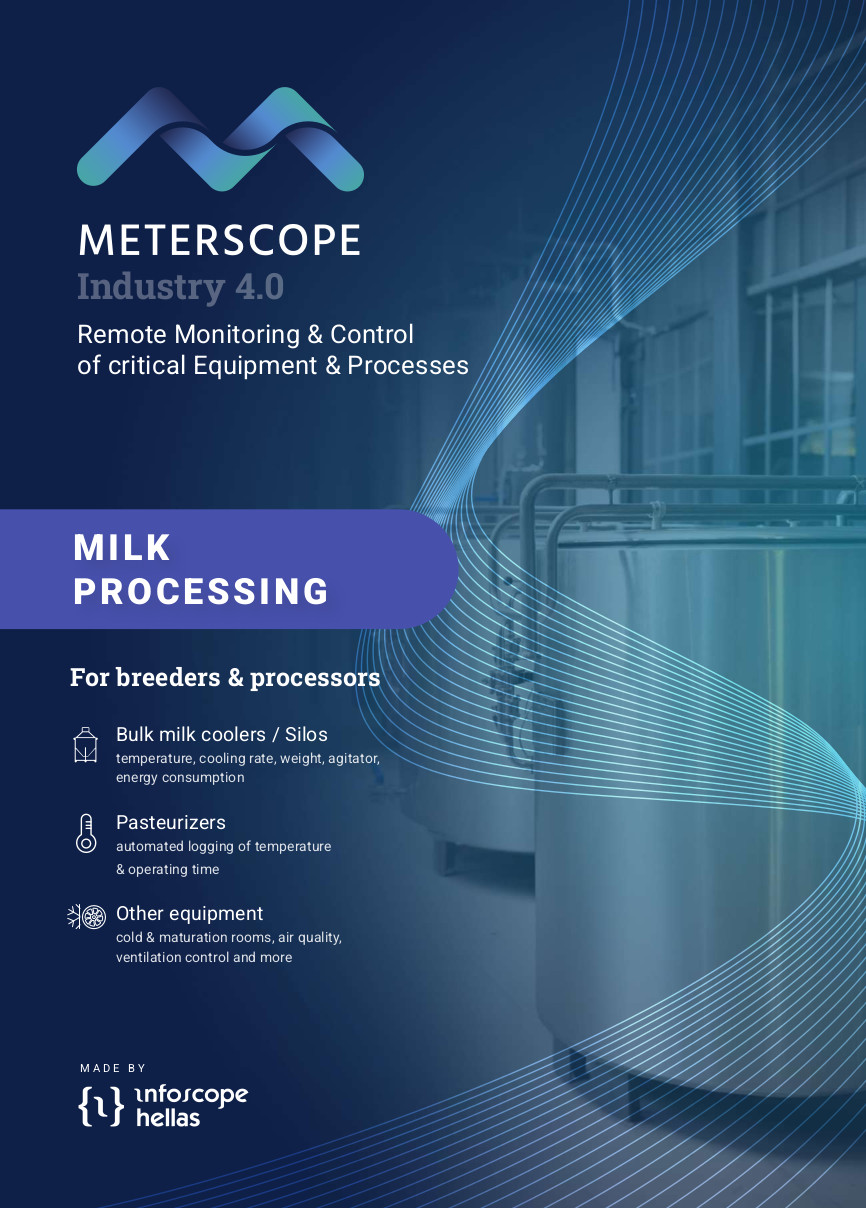

Meton Data Logger / Gateway at the service of the milk processing - Meterscope Manager as a tool in the dairy industry

More than 500 happy customers!

Pasteurizer

Pasteurizer

Monitoring heating condition, operating time, humidity, setpoint, offset. Close supervision only during operation

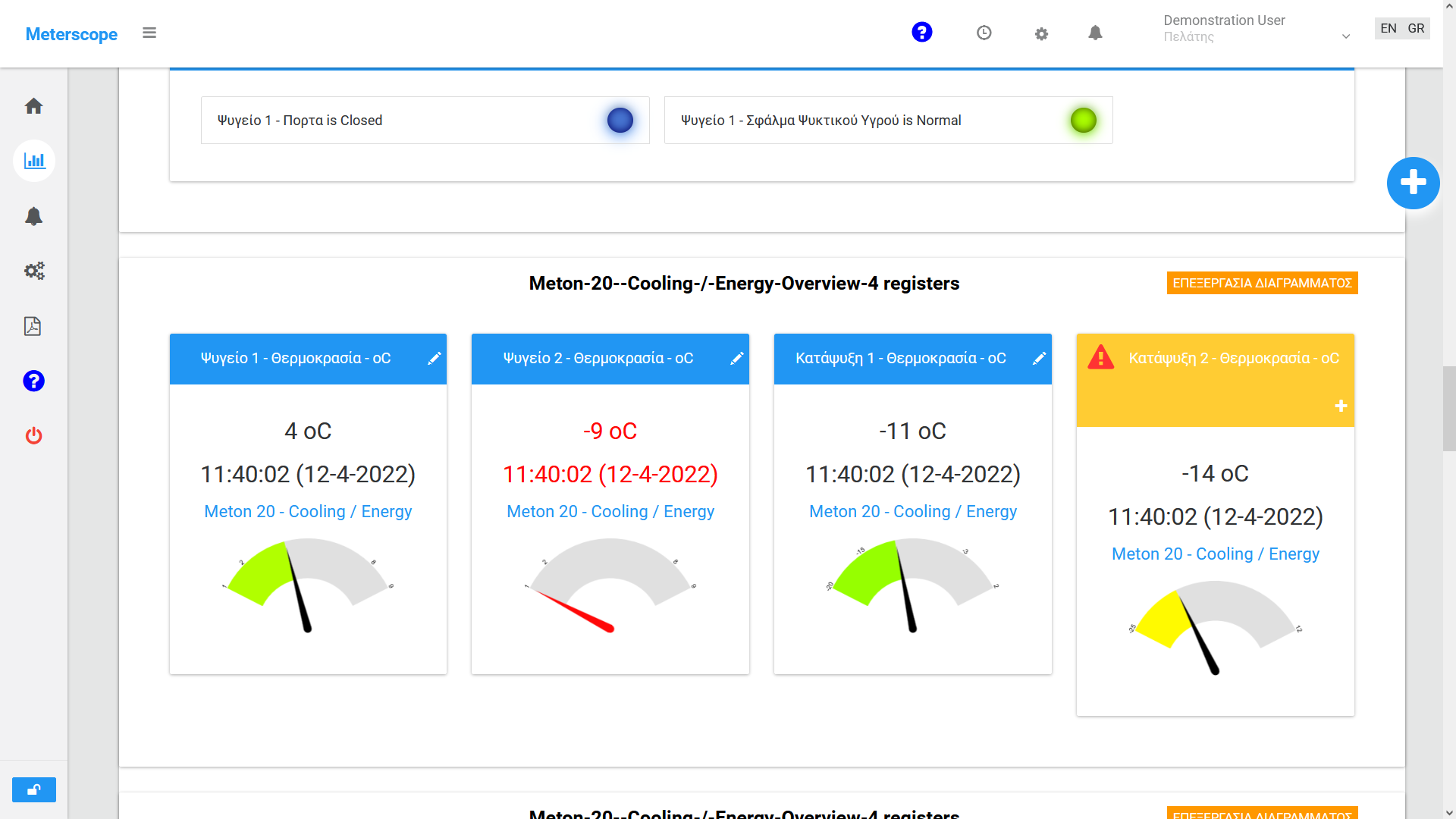

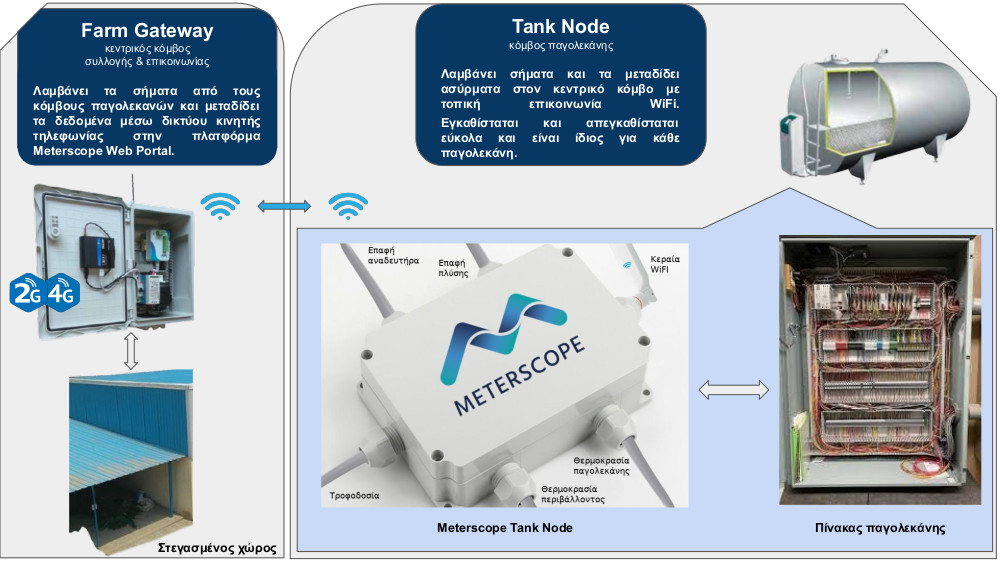

Bulk Milk Coolers / Silo

Temperature, weight, level and stirring logs

General equipment

Temperature, cooling procedure, milk processing and storage monitoring

Farms / Animal Breeding Units

Weight Measurement

Cost effective and non-intrusive sensor placement on the silo/bmc output externally, with weight calculation using innovative software that adapts to each geometry type (vertical, horizontal, cylindrical, oval etc) and size.

Weight recording provides additional capabilities such as automatic equipment usage detection (start of filling/emptying) and process duration (cooling rate).

Temperature Recording

Temperature data acquisition using additional sensors and/or directly from the silo/BMC controller. Equipment performance check adjusts to different processes (warm milk intake, cooling process, storage, washing etc) to achieve proper monitoring for each stage without false alarms.

Temperature data acquisition using additional sensors and/or directly from the silo/BMC controller. Equipment performance check adjusts to different processes (warm milk intake, cooling process, storage, washing etc) to achieve proper monitoring for each stage without false alarms.

An additional ambient temperature recording sensor provides alerts for extreme external temperatures and provides data for comparative studies.

Agitators' monitoring

Sensor monitoring the operation of the agitators (start / stop / duration) and detection of problematic conditions (overloading, malfunction).

The combination of the above data (weight, temperature) enables the system to accurately estimate when the agitators should be operational or not, and to provide the appropriate safety notifications.

Milk Processing Units / Cheese Factories

Central Monitoring

Capability to integrate all devices within the facility (silos/tanks, ice banks, refrigerators, product storage/aging chambers, pasteurizers, etc.) and receive data directly from the controllers of the existing equipment

Specialized recording

Recording of high temperatures and customized supervision of specific devices (pasteurizers) with automatic recording initiation per minute during the pasteurization process.

Scalability

Wide range of expansion possibilities with wireless temperature/humidity sensors, retrospective addition of new points of interest, energy consumption monitoring etc

Features and benefits

- Accurate pasteurization temperature assurance — Start/stop logs, heating function, setpoint, humidity, and offset monitoring

- Comprehensive equipment supervision — Cooling procedures, milk processing, and product storage

- Integration with existing equipment — Data collection from silos, bulk milk coolers, pasteurizers, and cooling devices

- High-frequency data logging — Close monitoring with minute-by-minute readings during pasteurization

- Consistent quality assurance — Achieving low microbial load in every batch

- Preventing food loss, supporting sustainability goals and improving quality

- Time saving & streamlined compliance with HACCP / ISO protocols

- Automated weekly report for each interconnected device of the equipment, pointing out deviations / potential malfunction

Why us

- Specialized team of engineers with extensive experience in Greece and Europe, ready to craft a turn-key solution tailored to your needs

- Extensive partner network and top customer support

- Collaboration with leading sensor manufacturers

- Subscription service with clear pricing policy, free after-sales support and updates

- Preconfigured data logger, no software installation is required, the updates are performed automatically without user interference

- EN12830 compliance for valnurable product temperature monitoring

- Designed in Greece / Produced in the EU

Milk collection, storage & processing supervision: Low microbial load, milk loss prevention, quality assurance

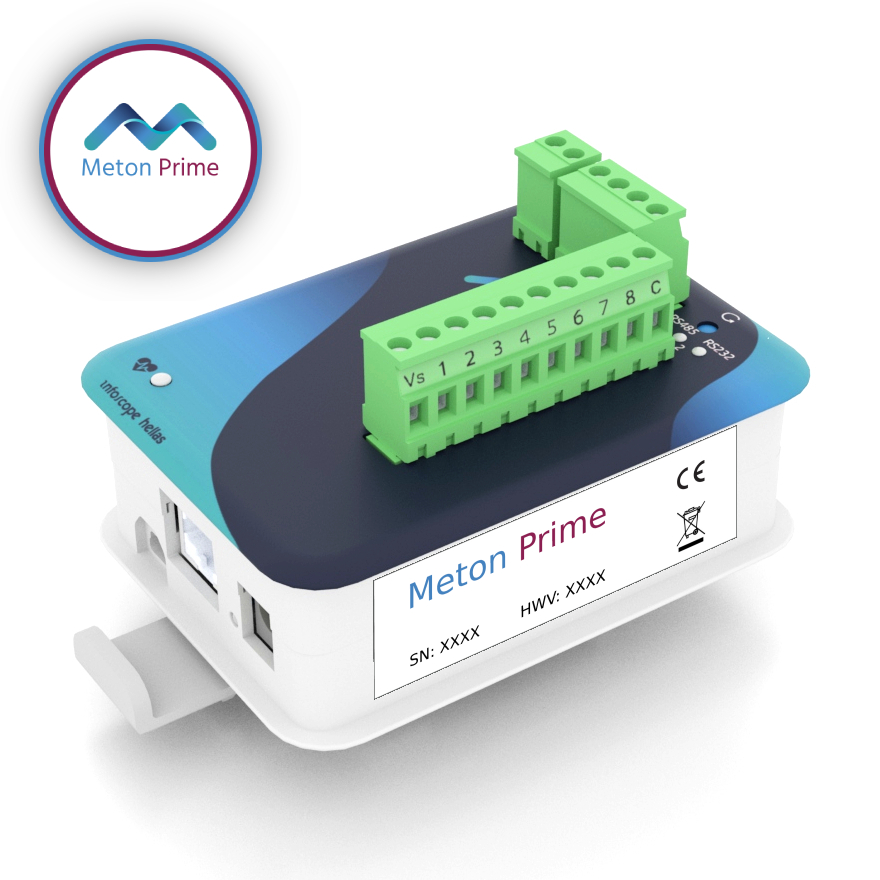

Temperature Data Logger - Meton Sense & Sense Plus

Τemperature / humididty / digital input data logger supporting 8 on board inputs and expansion modules

- Cold rooms, refrigerators, curing chambers, kettles, ovens and custom equipment temperature

- Digital input (normally open/normally closed, function) & outputs (relay, siren, light)

- Extensive sensor options (RTDs: Pt100, Pt1000, 2 or 3 wire, Thermistors: NTC or PTC, Thermocouple K, J, generic signal transmitters 4...20mA, 0-10V) for a vast temperature range (-200°C to +1800°C), high metering accuracy and long-distance coverage with the Meton Sense Plus

Meton Sense - Wireless Addon Extra Features

- Wireless sensors allowing for extra long battery life (up to 14 years!) &

- Industrial communication protocol, providing strong encryption

- Long range reception, covering whole building blocks / serveral floors in urban area

- Waterproof IP65, polycarbonate cabinet

- Autonomous internet connection (3G Modem) for stand alone installation or fallback handling in case of bad network

- Power supply back up (UPS) for energy autonomy and monitoring under power outage condition

Read more about the Wireless Addon of Meton Sense

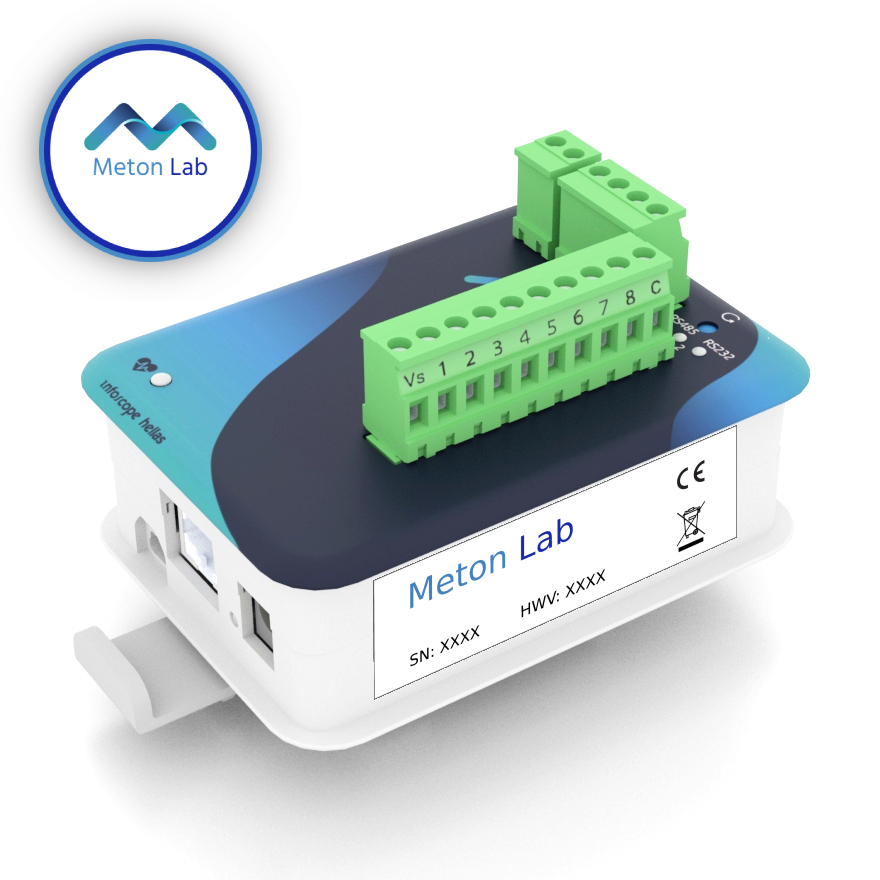

Device Controllers' Gateway - Meton Connect & Connect Plus

Collecting data directly from the interconnected devices' controllers

- Recording of data (temperature, operational status of individual components, digital contacts) of cooling control devices, refrigeration chambers, refrigerators, freezers, product storage areas, etc. Interfacing with a variety of controllers (e.g., Dixell, Pego, Eliwell, LAE, etc.) widely used in professional spaces that support the Modbus Protocol

- Monitoring of energy data (energy consumption, power, network voltage, current) in conjunction with a smart energy meter

- Capability to collect analog/digital data from integrated sensors with Meton Connect Plus

Contact us for more information, demo account or invoice!