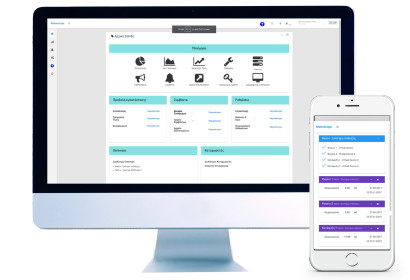

Monitoring temperature and device status in professional environments can be challenging due to the risk of excessive or false alarms. With advanced solutions like the Meterscope, users can create sophisticated rules to filter out unnecessary alerts.

This means receiving notifications only when they truly matter. Automated weekly reports further enhance monitoring, providing insights into equipment performance and helping professionals work more efficiently.

Stay ahead of the curve in temperature monitoring with Meterscope.

#TemperatureMonitoring #Meterscope #Efficiency

One problem that all recording systems often face is that they can't differentiate when an alarm is real and requires immediate intervention and when the notification for an event is unnecessary.

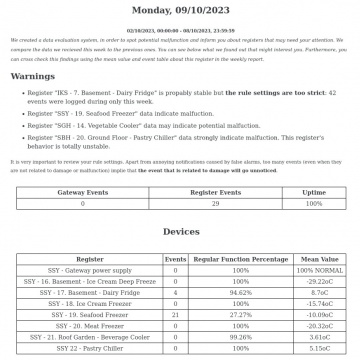

Apart from the nuisance it causes, a large number of security notifications can mean that an event accompanied by real damage will likely go unnoticed.

- Automatic weekly assessment: the user receives an email every Monday morning, presenting in detail the average performance of each device and highlighting areas that exhibit the greatest instability and/or frequently violate the operating limits. This way, it points out areas where sensor placement can be optimized for more representative temperature recordings.

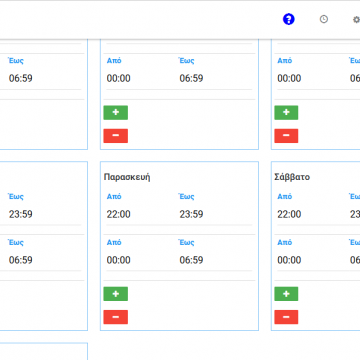

- Scheduling notifications: Events occurring at specific times - those resulting from known and unavoidable processes - are logged in the event file without simultaneous notification.

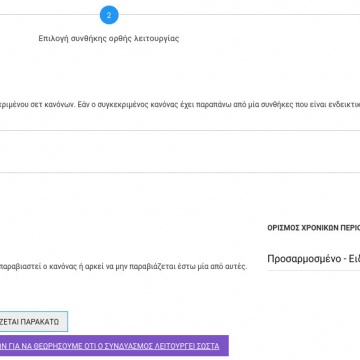

- Operating rule sets with scalable strictness: You have the option to choose rule sets with very strict limits, harmonized with the relevant HACCP/ISO standards, for marking events in the related file and a separate rule set with less strict limits, which implies a possibility of damage with simultaneous notification via email, SMS, and/or phone, depending on the deviation from proper equipment operation or user preferences.

-

Complex and specialized configuration:

-

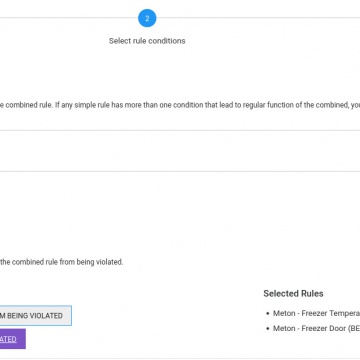

You can define the operating rules and choose that they only operate as part of a complex rule.

-

You can choose the combination that indicates malfunction (limit violations while the device should be operational and contains products) and the desired notification.

-

You can choose scheduling to avoid receiving notifications for cases when someone is on-site checking the status.

-

Now you will receive notifications only for events that deserve your attention.

The recording system should make the professional's life easier and not complicate it without a good reason.